|

|

|

AS 100 HORIZONTAL INTERMITTENT CARTONER-

Horizontal and vertical cartoners are primarily designed for packing various individual or multiple products into cartons of various sizes and shapes.

Flexible, cost effective solutions, outstanding quality and

reliability are common for for the complete range

of various machines.

The AS 100 is a automatic horizontal cartoning machine with continuous intermittent motion.

Final result: - Cardboard box completely closed with hot melt glued ends.

Machine specifications:

- Version:- Left hand ( the product flows from right to left seen from the front of the machine).

- Frame:- Heavy duty stainless steel welded frame. Machine designed for 3 shifts operation.

- Motion:- Intermittent motion with all movements mechanical driven not with pneumatic actuators.

- Bucket infeed conveyor:- Indexing motion from an enclosed intermittent cam unit. Chain pitch ¾". Buckets are stainless steel.

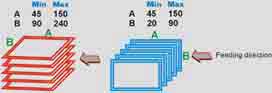

- Carton magazine unit:- Blank extraction by suction cups. Low level feeding height with low magazine inclination.

- Product loading:- Automatic from bucket conveyor with mechanical pusher.

- Carton conveyor:- Heavy-duty conveyor with four chain, ¾" roller chain.

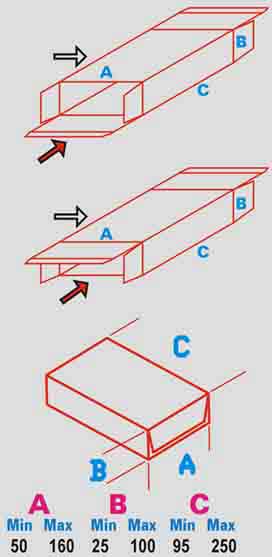

- Carton size adjustability:- Set-up hand-wheel controls with readout.

- Carton flap closing:- All flaps are closed by fingers cam driven.

- Side belt:- Flap compression after gluing by two belts and used also to horizontal discharge.

- Transmissions:- Driving made with timing belts HTD type. Hand-wheel drive for manual setting.

- Lubrication:- Machine without lubrication necessity of daily lubrication.

- Adjustments:- All adjustments set with hand wheels and mechanical digital readout. Quick release handles.

- Electrical control:- CE electrical components with electro-mechanical components with the following controls:

• Guards interlock switches

• Overload clutch

• No carton no load

• No product, no load

• Jam detector at product feed

• Carton magazine - low level

- Vacuum:- Pneumatic ejectors.

- Guards:- Guards all around machine.

- Drive:- Internal line shaft drives. All drives located outboard of product and carton conveyor.

OPTIONAL EQUIPEMENT

- Leaflet feeder.

- Extended carton magazine.

- Faulty display.

- Production counter.

- Pressure carton coder.

- Other electrical voltage and colors

- Spare parts kit.

This cartoner is offering wide capability of carton sizes and can handle variety of products.

TECHNICAL DATA |

AS 100 |

| Mechanical speed:- |

70 cartons/min |

| Power supply:- |

400 VAC/50 Hz |

| Power consumption - machine only:- |

2.5 KW |

Power consumption with

hot-melt installed:- |

8 KW |

| Air consumption:- |

4 Nl/cycle |

| Product change over time:- |

15 minutes |

| Weight:- |

1600 Kg |

Complete turnkeys packaging solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application.

AS 100 horizontal intermittent cartoner, product loading. |

AS 100 horizontal intermittent cartoner.

AS 100 horizontal intermittent cartoner.

AS 100 horizontal intermittent cartoner.

AS 100 horizontal intermittent cartoner.

AS 100 horizontal intermittent cartoner.

A100 horizontal intermittent cartoner.

|